“U” is a unit of measure in the audio and sound engineering domain, representing the standardized height for rack-mounted equipment.

One U equates to 1.75 inches or 44.45 millimeters, providing a uniform measure for equipment such as amplifiers, processors, or servers.

What is “U”? Table of Contents

As we navigate through our daily lives, we come across countless instances where certain units of measurement are integral, yet often overlooked. When we sip our morning coffee, we rarely consider the milliliters it’s measured in, or when we traverse city blocks, we seldom ponder about their standardized lengths. In the world of music production and sound engineering, such a ubiquitous but underappreciated unit is the “U.

So, What is “U”?

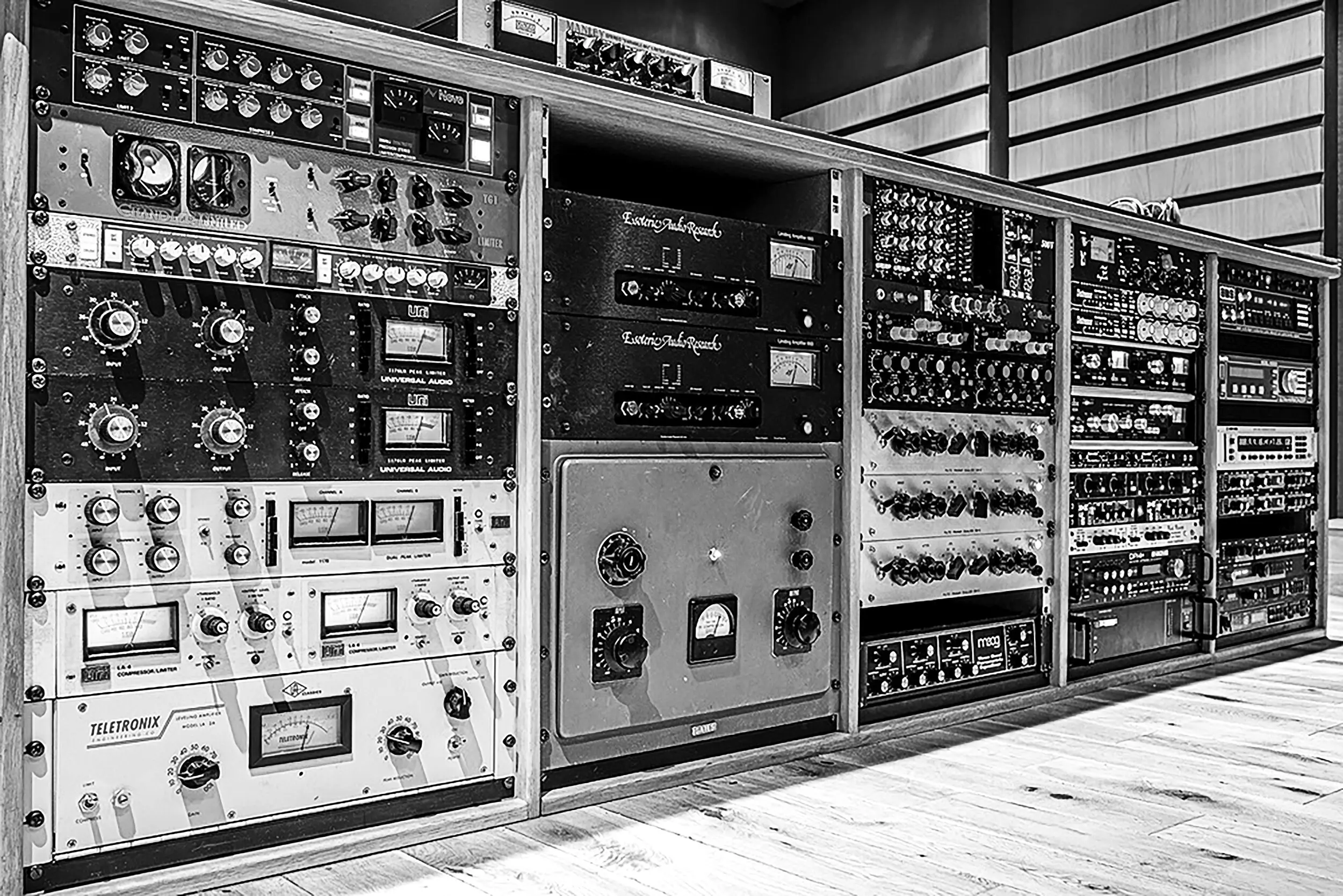

In its simplest form, “U” stands for a ‘Unit.’ It is a measurement standard, used extensively to define the height of equipment that is mounted on racks. These racks, as one might find in a recording studio, are often laden with various devices, from synthesizers and sound modules to effects processors and power conditioners.

A single ‘U’ or ‘rack unit’ corresponds to 1.75 inches or approximately 44.45 millimeters, and this measurement is an industry-standard regulated by the Electronics Industries Association (EIA) and the American National Standards Institute (ANSI). The system is designed such that each piece of rack-mountable equipment conforms to these dimensions. Therefore, the ‘U’ acts as a common language, a universal standard for sound engineers and music producers, allowing them to organize, configure, and interchange their equipment in a seamless and orderly manner.

In the following sections, we’ll delve deeper into this fascinating standard of measure, and explore why it’s so crucial in the world of sound engineering and music production. So whether you’re a seasoned producer, an audio engineering student, or someone with a keen interest in music technology, we invite you to join us on this journey of discovery.

What Does “U” Stand For in Music Technology?

Diving into the world of music technology, one is bound to encounter a series of terminologies, standards, and units. One such term that floats around with a veil of intrigue is the ‘U’. Now, you might be wondering, how does this ‘U’ relate to rack-mounted equipment and why is it so important?

The ‘U’, as we previously mentioned, represents a ‘Unit’ – a standardized measure used to define the height of equipment designed to fit on racks. But how does this translate to our everyday practical use? Well, to understand this, let’s first take a step back and imagine a typical music studio.

In any studio, large or small, a key aspect that one can’t ignore is the organization and management of equipment. From synthesizers and amplifiers to processors and patch panels, each piece of gear plays its unique role. But storing these myriad pieces of equipment in a clutter-free, accessible manner is a challenge that every music producer faces. Enter rack-mounted systems – a game-changer in studio organization.

These systems consist of a sturdy frame or cabinet known as a ‘rack,’ which accommodates various devices. Each rack is a standardized width of 19 inches but can vary in height. The height of these racks, and the equipment they house, is where our hero – the ‘U’ – steps in.

Every piece of rack-mountable equipment is designed to occupy a specific number of ‘rack units’ or ‘U’s. For instance, an amplifier might be designed to take up 2U, indicating it’s 3.5 inches tall. An audio interface could be 1U, meaning it’s 1.75 inches in height. This systematic approach allows for smooth equipment installation, removal, and adjustment. It also ensures that gear from different manufacturers will work harmoniously within the same rack, offering a great deal of flexibility to producers and engineers.

How is a “U” Measured?

Deciphering the dimensions of a rack unit can feel akin to trying to learn a new language. However, the beauty of the ‘U’ lies in its simplicity and uniformity. As we delve into the specifics of how a ‘U’ is measured, you’ll discover that it’s not just an abstract concept, but a tangible, practical measure that greatly simplifies the world of rack-mounted equipment.

So, how exactly do we measure a ‘U’? The answer to this is two-fold, involving both the vertical and horizontal dimensions.

On the vertical axis, one ‘U’ or ‘rack unit’ equates to exactly 1.75 inches, which translates to approximately 44.45 millimeters for those who prefer the metric system. These vertical units are stacked on top of one another in the rack, starting from the bottom. For instance, if you have a piece of equipment that’s designated as 2U, it would take up 3.5 inches of vertical rack space. Likewise, a 3U device would occupy 5.25 inches, and so on.

On the horizontal axis, there’s a standard width of 19 inches for all rack-mounted equipment. This means that no matter how tall a device is (in terms of ‘U’), it will always maintain a consistent width of 19 inches to fit snugly onto the rack. It’s also worth mentioning that while the ‘U’ typically applies to the height of rack-mounted equipment, the depth can vary significantly between different devices and is generally not standardized.

| Rack Space (U) | Height (inches) | Height (mm) | Standard Depth (inches) | Standard Depth (mm) | Standard Width (inches) | Standard Width (mm) |

|---|---|---|---|---|---|---|

| 1U | 1.75 | 44.45 | 19 | 482.6 | 19 | 482.6 |

| 2U | 3.5 | 88.9 | 19 | 482.6 | 19 | 482.6 |

| 3U | 5.25 | 133.35 | 19 | 482.6 | 19 | 482.6 |

| 4U | 7 | 177.8 | 19 | 482.6 | 19 | 482.6 |

| 5U | 8.75 | 222.25 | 19 | 482.6 | 19 | 482.6 |

| 6U | 10.5 | 266.7 | 19 | 482.6 | 19 | 482.6 |

| 7U | 12.25 | 311.15 | 19 | 482.6 | 19 | 482.6 |

| 8U | 14 | 355.6 | 19 | 482.6 | 19 | 482.6 |

| 9U | 15.75 | 400.05 | 19 | 482.6 | 19 | 482.6 |

| 10U | 17.5 | 444.5 | 19 | 482.6 | 19 | 482.6 |

But that’s not all there is to the story of ‘U’. What truly completes this measurement system are the rack holes, evenly spaced along the vertical rails of the rack. These holes are spaced according to EIA and ANSI specifications, with the distance from the center of one hole to the next being exactly 1.75 inches or 1U. This ensures that any rack-mountable device, irrespective of its manufacturer, will align perfectly with these holes, allowing for a smooth and secure installation.

Through this standardized measurement system, the ‘U’ serves as the bedrock upon which rack-mounted equipment is designed and used. It’s a system that embraces simplicity and efficiency, making it an indispensable tool for music producers and sound engineers.

How Did The “U” Unit Come to Be?

As with many things we take for granted today, the ‘U’ as a unit of measure has a rich history that spans several decades. Its origins lie in the birth and evolution of standardized engineering practices, which were set in motion by key organizations like the Electronics Industries Association (EIA) and the American National Standards Institute (ANSI).

The story begins in the early 20th century, when the proliferation of electronic devices led to a pressing need for standardization. Various pieces of equipment, whether radio transmitters or audio amplifiers, began to be manufactured in different shapes and sizes, creating a logistical nightmare when it came to organization and storage. Recognizing this challenge, the EIA, a trade organization representing the U.S. high tech community, stepped in to devise a solution.

In the mid-1900s, the EIA introduced the EIA-310-D standard, which established the specifications for what we now know as the 19-inch rack. The standard dictated that all rack-mountable equipment should be designed to fit within a 19-inch wide frame, with a height divisible by 1.75 inches or ‘U’. This standard was subsequently endorsed and adopted by ANSI, an organization responsible for overseeing and coordinating voluntary standards and systems.

The introduction of the EIA-310-D standard marked a turning point in the history of electronic equipment manufacturing. It enabled devices from various manufacturers to be racked together in a uniform and orderly manner, facilitating better space utilization and system integration. The ‘U’ unit, as we know it today, became the gold standard for defining the height of rack-mountable equipment, revolutionizing the way we set up and manage our studios.

Why Do We Use “U” in Rack Spaces?

You might wonder why such a specific measure as the ‘U’ holds so much weight in the realm of audio engineering and music production. Why not just rely on inches or millimeters for that matter? As it turns out, the implications and benefits of using the ‘U’ as a standard measure in rack spaces run deep, solving a myriad of practical issues and paving the way for a more organized, efficient studio setup.

The primary advantage of using the ‘U’ lies in its role as a universal language in the world of rack-mounted equipment. By standardizing the height of equipment to multiples of 1U, manufacturers across the globe can ensure their devices can seamlessly fit into any standard 19-inch rack, regardless of the brand or model of the rack itself. This compatibility extends to the users as well, who are saved from the hassle of having to check if a certain piece of gear will fit their rack or not. If it’s rack-mountable, it’s guaranteed to fit.

The use of ‘U’ in rack spaces also brings an undeniable level of order and organization to the studio environment. By aligning equipment to a standard measure, engineers and technicians can plan and optimize their studio setup with ease, knowing exactly how much rack space they need to allocate for each device. This simplifies the process of swapping gear in and out of the rack, offering a high degree of flexibility and adaptability.

Furthermore, the ‘U’ standard encourages better heat management. Devices mounted on a rack are usually designed with ventilation spaces that align with the ‘U’ system. This ensures heat produced by the equipment is dispersed efficiently, protecting the devices from overheating and potential damage.

Finally, the ‘U’ standard fosters innovation. Knowing the size constraints allows manufacturers to focus their energies on enhancing the features, functionality, and performance of their products without worrying about compatibility issues.

How Does “U” Affect Equipment Design?

The ‘U’ as a unit of measure doesn’t merely impact how we arrange our studios or manage our gear – it has profound implications on the very design of the equipment itself. The specific constraints dictated by the ‘U’ system play a pivotal role in shaping the architecture and layout of rack-mountable devices, influencing everything from the overall dimensions of a piece of gear to the placement of its components.

From a purely physical standpoint, the ‘U’ designation helps define the form factor of a device. Designers of rack-mountable equipment know from the outset that their device’s height must be a multiple of 1.75 inches, and its width must be within the standard 19 inches to ensure compatibility with the racks in use. This forms the initial blueprint from which they construct their designs.

However, the influence of the ‘U’ system goes beyond the exterior of the device and into its interior layout. Equipment designers must be savvy about the arrangement of components within the confines of the ‘U’ dimensions, especially as the number of ‘U’s decreases. In smaller devices, such as a 1U device, the placement of components and layout of circuitry becomes a matter of precision and meticulous planning. Designers must ensure that all necessary parts fit within the limited space while maintaining adequate room for ventilation and heat dissipation.

Moreover, designers must ensure the front-facing controls of the device are easily accessible within the allocated ‘U’ space. This often involves a creative and strategic layout of buttons, dials, and display panels. An overcrowded or poorly planned front panel could be detrimental to the user experience, no matter how well the device performs its function.

How Does Understanding “U” Benefit Music Producers and Technicians?

The understanding of the ‘U’ as a measure goes far beyond its simple arithmetic. In the landscape of music production and sound engineering, a grasp of this unit serves as a valuable tool, empowering professionals in a multitude of ways.

For music producers and studio owners, understanding ‘U’ provides a systematic method of planning and organizing their studio space. Whether setting up a new studio or revamping an existing one, knowledge of how many ‘U’s each piece of equipment occupies allows for a precise and efficient allocation of rack space. It’s a strategic game of fitting the puzzle pieces together in the most effective way possible, maximizing both space utilization and workflow.

Sound technicians, on the other hand, often find themselves dealing with a wide variety of equipment from various manufacturers. In this context, ‘U’ acts as a common language, ensuring compatibility across different brands and models. Knowing that every rack-mountable device adheres to this universal standard simplifies the task of assembling and integrating systems.

Moreover, the ‘U’ system offers clear cues for managing equipment heat dissipation. Devices are typically designed with their ‘U’ measurement in mind, incorporating ventilation spaces in alignment with rack units. An understanding of this allows technicians to ensure effective heat management, thereby prolonging equipment life.

In the realm of live sound or touring, professionals often need to move and set up equipment quickly and efficiently. The ‘U’ system facilitates this, making it easier to transport and install rack-mountable gear. Knowing the total ‘U’ space required by their equipment, they can pack appropriately sized portable rack cases.

From a broader perspective, understanding ‘U’ empowers music professionals to make informed decisions when purchasing new gear. By considering the ‘U’ size along with other specifications, they can ensure they’re investing in equipment that fits their available rack space and meets their production needs.

How to Calculate Rack Spaces Using “U”?

Calculating rack spaces using ‘U’ is a practical skill that can greatly streamline your studio setup and management process. By mastering this simple but potent art, you can ensure optimal use of your rack space and lay the groundwork for efficient and effective workflows. Let’s delve into the details of how you can put ‘U’ to work in your own studio.

Firstly, it’s essential to understand that ‘U’, as a unit of measure, is directly proportional to the physical height of your equipment. Each ‘U’ corresponds to 1.75 inches or 44.45 millimeters. So, a piece of equipment listed as 2U would occupy a height of 3.5 inches (or 88.9 millimeters) in your rack.

To calculate the total ‘U’ space that your gear will occupy, simply add up the ‘U’ measurements of each piece of equipment you plan to mount in the rack. For example, if you have a synthesizer that takes up 3U, an effects unit that takes up 2U, and an amplifier that takes up 4U, the total space they will occupy is 9U.

However, the total ‘U’ space isn’t the only thing to consider. It’s equally important to remember that rack-mountable equipment also needs space for ventilation to prevent overheating. To account for this, you may want to leave a gap of 1U between devices, especially between those known to generate a lot of heat.

In configuring your equipment layout, consider not just the ‘U’ size but also the practicality of the setup. Put equipment that you frequently adjust at eye level, and rarely-tweaked devices lower down. Also, consider the weight of the equipment, with heavier devices generally placed towards the bottom of the rack for stability.

Lastly, always ensure that your rack itself is of sufficient size to accommodate your gear. If you’ve calculated that your equipment will take up 20U, make sure you have a rack that’s at least 20U in size, keeping in mind any additional ‘U’ spaces you’ve allocated for ventilation.

Frequently Asked Questions About “U”

Music production and sound engineering can involve some complex technical concepts that can initially be overwhelming. The term “U”, an abbreviation for the modular unit in rack spaces, often prompts several questions among those new to the field. Here, we’ve collated and answered the most frequently asked questions about “U” and related concepts to help clarify these concepts.

What does 1U mean?

1U refers to a standard unit of measurement for rack mountable equipment where “U” stands for “Unit”. It’s equivalent to 1.75 inches or 44.45 millimeters.

How much does a rack unit (1U) weigh?

The weight of a 1U device varies greatly depending on the specific piece of equipment. The “U” measurement refers to the height, not weight.

What does 2U mean?

2U refers to the size of rack-mounted equipment that occupies the space equivalent to two rack units. It’s equal to 3.5 inches or 88.9 millimeters.

What does 4U or 5U mean?

These are multiples of the standard rack unit. For example, a 4U device is 7 inches high (four times 1.75), a 5U device is 8.75 inches high, and so on.

What does 6U or 7U mean?

Similar to other ‘U’ measurements, these terms refer to the size of rack-mounted equipment. For example, a 6U device is 10.5 inches high and a 7U device is 12.25 inches high.

What is a rack unit?

A rack unit or “U” is a standardized size used for mounting equipment in a rack. It’s equal to 1.75 inches.

What is a 19-inch rack?

A 19-inch rack refers to a standardized frame or enclosure used for mounting various equipment modules. Each module has a front plate that is 19 inches (482.6 mm) wide, including edges or ears that protrude on each side.

What does “rack mount” mean?

Rack mount refers to a method of securely installing equipment in a rack, usually by screwing the device’s faceplate into the rack’s round holes or square slots.

Why are rack units standardized?

Standardizing rack units simplifies the process of installing, operating, and maintaining hardware. It also ensures that equipment from different manufacturers can be used together in the same rack.

What is a half-rack unit?

A half-rack unit, often referred to as 0.5U, is exactly half the size of a standard 1U, meaning it measures approximately 0.875 inches or 22.22 millimeters in height.

How deep is a standard rack?

While the height and width of racks are standardized, depth is not. However, common depths for floor-standing racks are 600 mm (23.62 inches) or 800 mm (31.50 inches).

What is rack space?

Rack space refers to the total amount of room available for mounting equipment in a rack. It is measured in ‘U’ units.

How is rack space calculated?

Rack space is calculated by determining the number of ‘U’ units that a rack can hold. For example, a rack labelled as 20U has 20 rack spaces, each of 1.75 inches, available for equipment.

What does ‘U’ mean in server racks?

In the context of server racks, ‘U’ has the same meaning as in music production. It refers to the height of the server equipment, with 1U equal to 1.75 inches.

What is the distance between holes in a rack?

In a standard rack, the holes are evenly spaced at 0.625 inches (15.875 mm) apart from center to center, resulting in three holes per ‘U’ space.

What is a shockmount rack?

A shockmount rack is designed to protect sensitive equipment from vibrations and impact. It incorporates a suspension system (the “shock mount”) into the rack design.

What’s the difference between a rack and a cabinet?

A rack is a framework that holds equipment, whereas a cabinet is a rack enclosed by a casing to provide added protection and security.

Are rack standards the same worldwide?

Yes, the 19-inch rack standard and ‘U’ unit of measurement is universally adopted, making it easier to use equipment from different manufacturers together.