An acoustic or sound absorber is a material block, and sometimes a device, designed to reduce the level of sound waves in a specific space. These materials or devices work by absorbing sound energy and converting it into heat, thereby lowering the overall level of noise in a space. The use of absorbers can also help to control reverberation and echo in a room by reducing sound propagation to zero. This makes the space sound less “live” and more “dead,” while also improving overall sound quality.

Applications: What are absorbers used for?

Absorbers can be used in a variety of applications. Concert halls, for example, use absorbers to reduce the amount of sound reflected off surfaces, thereby improving overall sound quality for the audience. Absorbers can be used in a recording studio to control the amount of sound that reflects off of surfaces, which helps to improve the overall sound quality of recordings.

Absorbers are also used in industrial facilities to reduce noise pollution and protect employees’ hearing. In the home, absorbers can be used to improve the overall sound quality of movies and music in home theaters. Absorbers are used in offices to reduce noise pollution and improve speech intelligibility. Absorbers are used in gyms and fitness centers to reduce noise and protect the hearing of employees and customers.

What are the three types of acoustic absorbers?

There are three main types of acoustic absorbers:

- Porous absorbers: Materials with a high sound absorption coefficient, like fiberglass, rockwool, or foam, are used to create these absorbers. These materials are useful in many different contexts due to their ability to absorb a wide range of sound frequencies. Porous absorbers are a common fixture in many different types of spaces, including performance venues, studios, factories, home theaters, and even workplaces.

- Resonant absorbers: These are are a particular kind of acoustic absorber that transforms sound energy into heat using a mechanical or electrical system. They are frequently used in industrial settings where there is a lot of noise because they are made to target specific sound frequencies. The majority of these absorbers are made of a panel or membrane that vibrates when sound waves strike it, releasing its energy as heat. The panel or membrane is then tuned to a specific frequency and suspended in a frame to maximize its efficiency. In factories, power plants, and other industrial facilities where reducing noise pollution is a top priority, resonance absorbers are frequently used. They are also utilized in some musical instruments, including drums, to regulate the sound’s sustain. Resonant absorbers can be a very efficient way to lower noise pollution in industrial settings because of their ability to focus on specific frequencies.

- Hybrid absorbers: These absorbers combine the characteristics of porous and resonant absorbers.

What are examples of absorbers of sound?

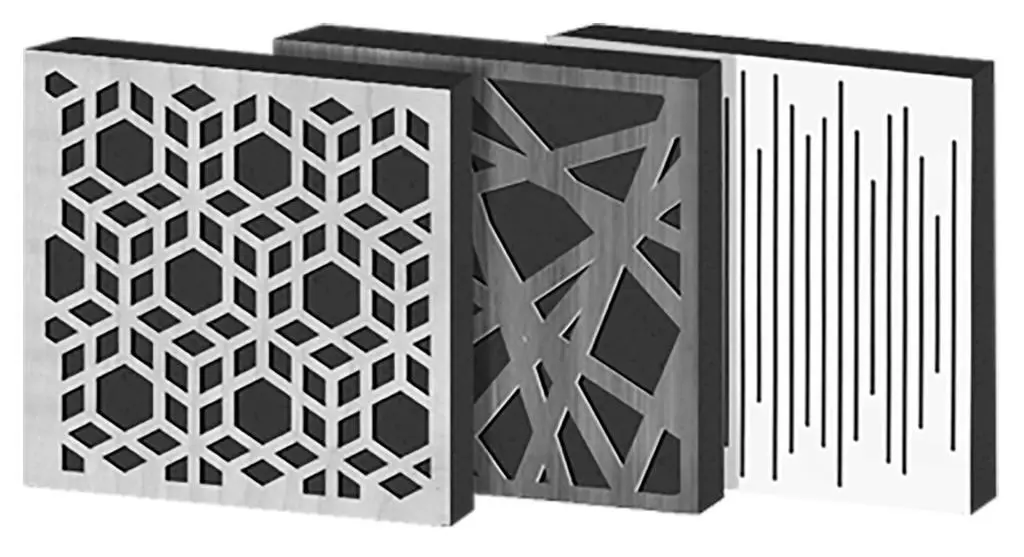

Absorbers come in a variety of shapes and sizes, and they differ due to the materials and products that are used to absorb, block, and isolate sound and heat. You can find them as follows:

- Sound absorbing panels: They are typically made from a range of materials such as fiberglass, foam, rockwool, or other porous materials that are designed to absorb sound waves and reduce the level of reflected sound.

- Sound absorbing blankets / sheet: Also known as acoustic blankets or soundproofing sheet, are a type of soundproofing material used to reduce the amount of sound entering and exiting a room. They are typically made of thick, dense materials that can absorb a wide range of frequencies, such as fiberglass, mineral wool, or foam.

or even

- Sound absorber walls: Typically, they are composed of sound-absorbing insulation, heavy-duty drywall, and acoustic sealant to form an effective sound barrier.Sound absorber walls can be constructed as new construction or retrofitted to existing walls, making them a flexible solution for sound control in recording studios, home theaters, offices, and other settings where sound control is essential.

- Sound absorbing tiles: Sound absorbing tiles: The echo and reverberation in a room can be diminished by installing these tiles on the walls, ceiling, or floor. Porous materials like fiberglass, mineral wool, or foam are typically used because of their ability to absorb sound across a wide frequency range.