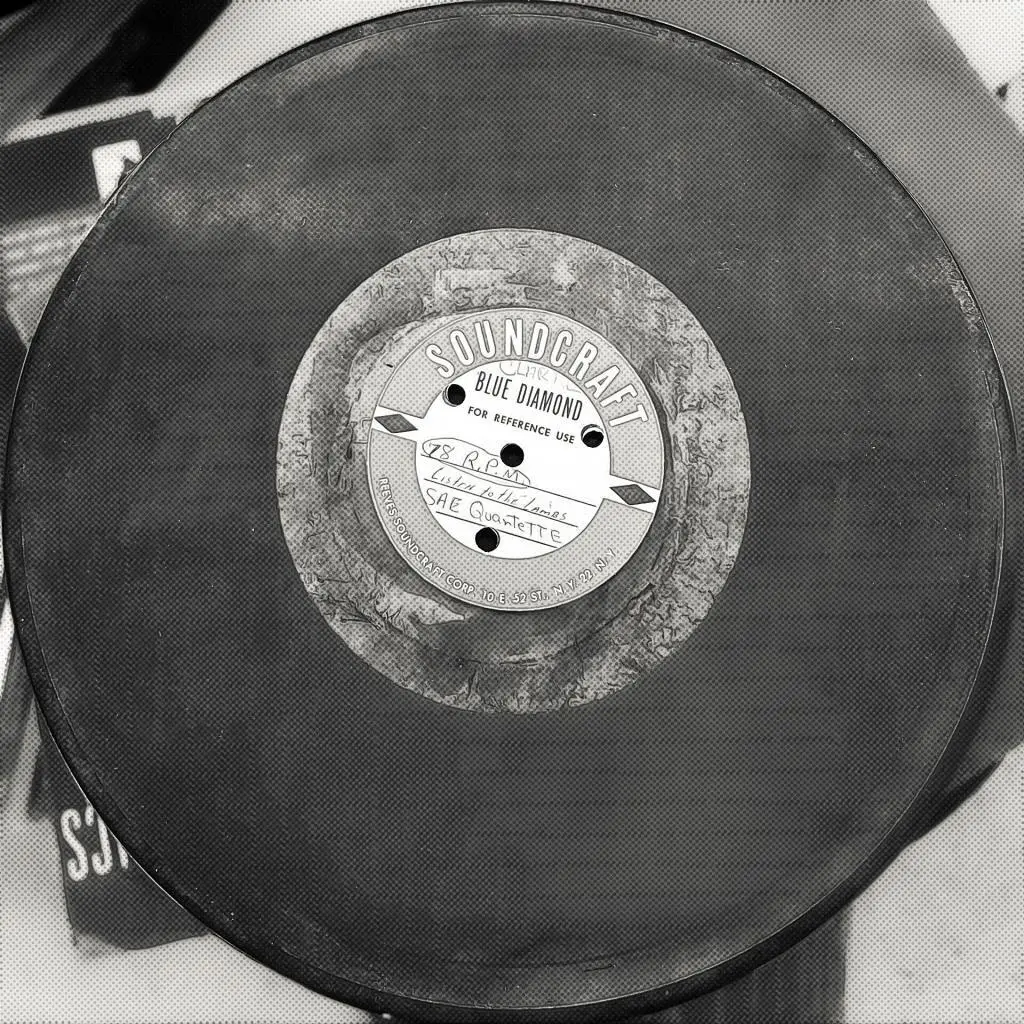

Acetate discs, also known as lacquers, are a type of plastic disc used in music production to play back audio recordings.

They are made of a material similar to that of a vinyl record, but they are not intended for mass production or commercial release. Instead, they serve as reference copies or test pressings for songs or albums before they are finalized and released commercially.

What is Acetate: Table of Contents

If you’re a music aficionado, you might have heard of “acetate” discs. Despite their name, these professional grade discs don’t actually contain any acetate. Instead, they consist of an aluminum core disc coated with nitrocellulose lacquer. During World War II, glass was commonly used as the substrate due to the shortage of aluminum.

Why Are They Called “Acetate” If They Don’t Contain Acetate?

The use of the term “acetate” is a misnomer that has persisted over time. Some early lacquer disc labels carried the warning “Use only acetate needles,” which referred to the high grade of individually inspected steel needles required to safely play the easily needle-damaged pressed flexible acetate transcription discs that were sometimes used in US broadcasting in the 1930s. Instantaneous disc history authority Michael Biel attributes the longstanding “acetate” misnomer to this.

A Brief History and Legacy of Acetate Discs in Music Recording

The history of acetate discs dates back to the early 20th century, when the music industry was looking for new ways to produce and distribute music recordings. The invention of the phonograph and the gramophone had revolutionized the industry, but it was still limited by the technology of the time. In 1930s, a new type of disc called acetate discs emerged as a way to create high-quality recordings quickly and easily.

In the 1930s, acetate discs were first used as a type of recording media for sound recordings. These discs were made of a metal core coated with a layer of nitrocellulose lacquer, which was used to record the sound. They were often used to create master recordings, which would then be used to create vinyl records for sale to the public.

During World War II, there was a shortage of aluminum, which was used to make the metal cores for acetate discs. As a result, glass was often used as a substrate instead. This led to a change in the production process and resulted in a disc that was different in several ways from the vinyl records sold to customers at retail.

The production of acetate discs became more widespread in the 1940s. They were commonly used for recording radio broadcasts, as well as for creating master recordings. At the time, they came in a variety of sizes, from less than 7 inches (18 cm) to more than 16 inches (41 cm) in diameter.

In the 1950s, acetate discs were largely replaced by magnetic tape as a recording medium. However, they continued to be used for making master recordings for many years, and they remain an important part of the recording process even today.

The Making of Acetate Discs: A Comprehensive Look at the Production Process

The production process for acetate discs is an intricate process that involves several steps to create a final product that can be used to make vinyl records for sale to the public. The following is a detailed breakdown of the production process for acetate discs:

Step 1: Master Recording

The first step in the production process for acetate discs involves creating a master recording of the desired audio. This recording is typically made on magnetic tape, which is then used to create a lacquer-coated metal or glass disc.

Step 2: Cutting

The second step in the production process involves cutting the sound into the lacquer-coated metal or glass disc using a cutting lathe. This process involves a highly skilled technician who uses a cutting head to engrave the audio signal into the lacquer coating. The cutting head is guided by a computer program that controls the depth and speed of the cut.

Step 3: Electroplating

After the sound has been cut into the lacquer-coated disc, the disc is then electroplated with nickel. This process creates a stamper, which is used to create vinyl records for sale to the public. The electroplating process involves immersing the lacquer-coated disc in a solution of nickel sulfate and applying an electrical current to it. This causes the nickel to deposit onto the surface of the disc, creating a negative impression of the sound that was cut into the lacquer coating.

Step 4: Stamper Production

Once the nickel has been deposited onto the disc, it is removed and cleaned, leaving behind a negative impression of the sound. This negative impression is then used to create a positive stamper. The stamper is a metal disc with a positive impression of the sound that was cut into the lacquer coating. This stamper is then used to press vinyl records for sale to the public.

Step 5: Vinyl Record Production

The final step in the production process for acetate discs involves using the stamper to press vinyl records. This process involves heating vinyl pellets and pressing them between the stamper and a vinyl substrate. The heat melts the vinyl, which then fills the grooves in the stamper, creating a vinyl record with the same sound as the original recording.

Uses of Acetate Discs: From Record Mastering to Radio Broadcasting

Acetate Discs for Quality Control in Record Mastering

Acetate discs have been used in the mastering process for vinyl records since the early days of the industry. Before the production of stampers used to create retail copies of the record, test acetate discs are used for quality control. These reference disks allow the artist, producer, engineer, and other interested parties to check the quality of the tape-to-disc recording process and make any necessary changes to ensure that the audio fidelity of the master disc will be as close as possible to that of the original master tape. The actual stamper sets can be made either from oversized lacquers or from DMM blanks (see Direct Metal Mastering).

Acetate Discs for Direct Recording

Before magnetic tape became common, disc recording was done “live”, although sometimes intermediate disc-to-disc editing procedures were involved. Before acetate discs were adopted for the purpose, the master recording was cut into a disc of wax-like material that was too soft to be played non-destructively and had to be electroplated to produce a metal stamper, which was in turn used to make playable pressings. Acetate blanks allowed high-quality playable records to be produced “instantaneously”.

Acetate Discs in Radio Broadcasting

Acetate discs were widely used in radio broadcasting before the introduction of magnetic tape. They were used to archive live broadcasts, pre-record local programming, delay network feeds for broadcast at a later time, and provide programming “from home” on the Armed Forces Radio Network. 16-inch (41 cm) discs recorded at 33+1⁄3 rpm were used for these one-off “electrical transcriptions” beginning in the mid-1930s. In many cases, the AFRN disc is the only form in which a classic radio show has survived.

Acetate Discs for Amateur Home Use

Disc recorders designed for amateur home use began appearing on the market around 1940, but their high prices limited sales, and then World War II brought their production to a halt. After the war, the popularity of such recorders greatly increased. It was not unusual for a carnival, circus, amusement park, or transit hub to offer disc recording in a booth for a modest fee. Countless discs were cut at parties and family gatherings, both for immediate amusement value and to preserve audio “snapshots” of these events and of the voices of relatives and friends.

Acetate Discs as Research Tools

This relatively bulky equipment, and the bulky discs, were hauled to remote locations by ethnographers, linguists, and musical researchers. Substantial collections of these recordings are available to researchers at academic and national libraries, as well as museums.

High-Value Acetates: Collectible Vinyl Records Worth Their Weight in Gold

Acetates are the rarest and most sought-after form of vinyl records due to their limited production runs. These recordings were originally used as a way to test the sound quality of a new release before mass-producing it on traditional vinyl. Today, acetates hold a special place in the hearts of collectors and audiophiles, and some can fetch incredibly high prices at auction.

The Beatles Acetates: A Collector’s Dream

Acetates from The Beatles are some of the most valuable and sought-after recordings in the world. Brian Epstein, the band’s manager, had a collection of Beatles acetates that sold for between $1,000 and $10,000 per disc at auction. Some rare recordings even fetched up to £77,500. These acetates are highly prized due to their historical significance and rarity.

The Velvet Underground Acetate: A Hidden Gem

In 2006, an acetate from The Velvet Underground was sold on eBay for a whopping $25,200. The recording contained music that would later appear on the band’s first album, The Velvet Underground & Nico. This particular acetate is a testament to the band’s influence and importance in the world of music.

Elvis Presley Acetates: A King’s Ransom

Elvis Presley acetates are also highly collectible and valuable. In 2013, an acetate of his hit song “That’s All Right” sold for an incredible $82,393.60 at auction. However, the most valuable Presley acetate is the only known copy of his first recording, featuring “My Happiness” and “That’s When Your Heartaches Begin.” This 78 rpm acetate from 1953 sold for a staggering $300,000 at a Graceland auction.

The Value of Acetates: A Wise Investment

For collectors and audiophiles alike, acetates are a wise investment due to their rarity and historical significance. These recordings offer a unique glimpse into the music-making process and are highly sought after by those looking to own a piece of music history. While some acetates can command incredibly high prices, they are a valuable addition to any serious music collection.

FAQs: Answering the Top Questions about Acetate

This section contains concise answers to the most frequently asked questions about acetate that have been submitted via the search bar. Rest assured that we regularly update this section as new queries come in.

Are acetate discs the same as vinyl records?

No, acetate discs are not the same as vinyl records. While they are both used for audio recording, acetate discs are made from a different material and are generally less durable than vinyl records.

How acetate discs are they different from vinyl records?

One of the most noticeable differences between acetate and vinyl records is their weight and flexibility. Vinyl records are lighter and more flexible, while acetates are heavier and more rigid due to their metal cores. Acetates typically come in two sizes: 10-inch discs for singles and 14-inch discs for albums.

How long do acetate discs last?

Acetate discs are not very durable and can degrade over time, so they typically have a shorter lifespan than vinyl records. With proper care and storage, however, they can last for several decades.

Can acetate discs be played on a regular turntable?

Acetate discs require a special type of turntable called a transcription turntable, which has a heavy tonearm and a special cartridge designed for playing acetate discs.

How do you clean acetate discs?

Acetate discs should be cleaned using a soft, lint-free cloth and a gentle cleaning solution specifically designed for use on acetate discs.

Are acetate discs still used for recording today?

While acetate discs are not as commonly used as they once were, they are still used by some recording studios for mastering and demo recordings.

Are acetate discs still being manufactured?

Acetate discs are still being manufactured, but they are not as widely used as they once were. Some companies still produce acetate discs for use in mastering and demo recordings.